Intervista Biagio Lamanna

"What are they doing over there?"

When did CAREL’s Thermodynamic Research center open, and why?

The so-called Thermodynamic Research center, or more precisely the Research center for HVAC/R applications, started operating between 1998 and 1999. At the time, CAREL's strategy of focusing on customer applications and needs, especially those that were not expressed, was already evident. To study air conditioning and refrigeration applications more in depth, the then Vice President Luigi Nalini recognised it was necessary to have the same equipment that CAREL's customers used in their own research labs. Consequently, CAREL's first applied thermodynamics research center was created, built around a climate test chamber that was able to reproduce the temperature, humidity and air flow conditions of an air-conditioned space.

The so-called Thermodynamic Research center, or more precisely the Research center for HVAC/R applications, started operating between 1998 and 1999. At the time, CAREL's strategy of focusing on customer applications and needs, especially those that were not expressed, was already evident. To study air conditioning and refrigeration applications more in depth, the then Vice President Luigi Nalini recognised it was necessary to have the same equipment that CAREL's customers used in their own research labs. Consequently, CAREL's first applied thermodynamics research center was created, built around a climate test chamber that was able to reproduce the temperature, humidity and air flow conditions of an air-conditioned space.

CAREL was thus a forerunner, as back then it was unique for companies such as ours, which manufactured components and not units, to have its own research lab.

How was the center set-up at the beginning? What were its main activities?

I started my long career at CAREL in April 2000.

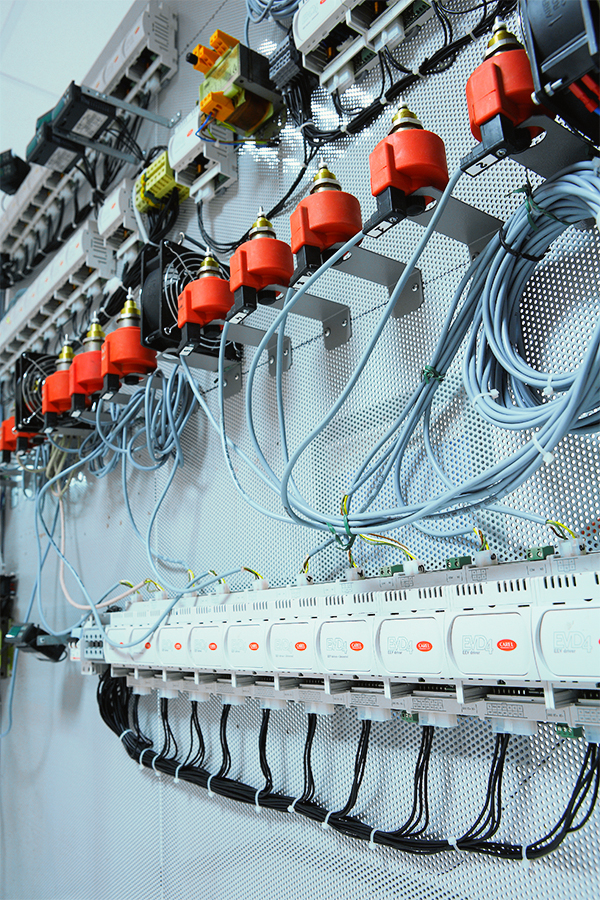

At the time, the research center was located in the same street as Headquarters, but not in the same building, where electrical panels are now manufactured. To be honest, that location was halfway between strategic and "what are they doing over there?". The research center was in fact the farthest wing from the main CAREL building, out on the "edge" of the company's main activities, yet at the same time offering an undisturbed place to work. In addition to the climate test chamber, the research center featured various types of testing and measuring equipment, and obviously units for the applications served by CAREL's customers: data center air conditioners, water chillers and refrigerated cabinets.

The work revolved around three main projects: analysis of ice formation inside supermarket refrigerated showcases, the control logic of water chillers, and the first prototypes of one of the products that would later mark CAREL's history: the electronic expansion valve.

How many people worked there? What were the first solutions developed thanks to the work done at the research center?

The research center was initially staffed by a team of young undergraduates from the University of Padova, working on their degree theses.  These research projects were developed thanks to the excellent relationship between Luigi Nalini and Renato Lazzarin, who would later become president of the Italian Association of Air Conditioning, Heating and Refrigeration from 2008 to 2010. There were also two full-time technicians with expertise in electrical and heating engineering. The very first CAREL employee to work at the research center was Alessandro Greggio, who today manages the Group's Refrigeration Sales & Marketing department. That was back in September 1999. I was the second. In the space of a few years, three more staff were added, including colleagues who subsequently used the skills acquired to further their career in the company as platform managers or marketing specialists.

These research projects were developed thanks to the excellent relationship between Luigi Nalini and Renato Lazzarin, who would later become president of the Italian Association of Air Conditioning, Heating and Refrigeration from 2008 to 2010. There were also two full-time technicians with expertise in electrical and heating engineering. The very first CAREL employee to work at the research center was Alessandro Greggio, who today manages the Group's Refrigeration Sales & Marketing department. That was back in September 1999. I was the second. In the space of a few years, three more staff were added, including colleagues who subsequently used the skills acquired to further their career in the company as platform managers or marketing specialists.

One of the first solutions developed at the research center was "smart defrost", a defrosting management system for refrigerated showcases. It was first included in what was at the time a highly-innovative controller, Mastercase, a product now in its third generation that laid the foundations for one of CAREL's most successful products, MPXPRO.

And obviously the first control system for electronic expansion valves, EVD100, progenitor of the current EVO Evolution, another of CAREL's most successful products, with a career spanning more than 15 years!

"Electronic expansion valves and drivers have marked the success of the thermodynamic research center and form the heart of many CAREL solutions."

What were the main difficulties or challenges at the beginning?

The first real challenge was to place the research center into the corporate context. In fact, all the work done and the equipment used were somehow "different" from the rest of CAREL. This gave us continuous ideas for improving day-to-day management, starting from purchasing, to transport logistics ("Biagio, there's a truck here with two huge refrigerators, where can we put them?"), and even admin concerning the equipment. Subsequently, the introduction of electronic expansion valves raised the bar in terms of challenges. CAREL had always been used to working on electrical and electronic products that interact with refrigeration units from inside an electrical panel.

The first real challenge was to place the research center into the corporate context. In fact, all the work done and the equipment used were somehow "different" from the rest of CAREL. This gave us continuous ideas for improving day-to-day management, starting from purchasing, to transport logistics ("Biagio, there's a truck here with two huge refrigerators, where can we put them?"), and even admin concerning the equipment. Subsequently, the introduction of electronic expansion valves raised the bar in terms of challenges. CAREL had always been used to working on electrical and electronic products that interact with refrigeration units from inside an electrical panel.  These valves, on the other hand, interacted directly with the refrigerant circuit. So rather than voltage, current or electromagnetic disturbance, we needed to work with pressure, temperature, oil and piping. Not to mention that our production department was expert in electronic boards and humidifiers, but not yet in precision machining. These skills were not yet widely available in the company. This is why in the early years, the research center staff directly "accompanied" the product along its long and tortuous journey from testing to the customer, managing production, logistics, before- and after-sales activities.

These valves, on the other hand, interacted directly with the refrigerant circuit. So rather than voltage, current or electromagnetic disturbance, we needed to work with pressure, temperature, oil and piping. Not to mention that our production department was expert in electronic boards and humidifiers, but not yet in precision machining. These skills were not yet widely available in the company. This is why in the early years, the research center staff directly "accompanied" the product along its long and tortuous journey from testing to the customer, managing production, logistics, before- and after-sales activities.

I won't deny that the challenge was quite arduous at times, but it paid off in terms of skills acquired and results.

How has the center developed over the years? And what are the plans for the future?

In 2005, the research center moved to the main CAREL building, after significant expansion. That was when the first "research center" production lines for electronic valves were set up. When moving, we purchased and retrofitted an additional climate test chamber, previously owned by Uniflair, a customer of ours that dealt with air conditioning applications for data centers and telecom applications. The research center was extended to cover a total area of 600 m2, capable of hosting many other applications. Examples of these include heat pumps, air handling units, a machining area and finally the famous showroom. This was a hybrid space for hosting demos and welcoming visitors from outside the company, simulating a small supermarket. Over the years, this space has seen many different technologies, refrigerants and thousands of people, including the colleagues from our branches who have done training courses there.

After 2010, with CAREL's exponential growth, the need arose for local R&D centers. The two areas where we were most established were China and the USA, and in 2014 (China) and 2015 (USA) two more research centers were created, mainly working on local projects. Clearly, at the beginning, there were some difficulties regarding coordination and transfer of methods and standards, so several colleagues moved to these local research centers for a few months to help get them up and running.

Today, more than 20 people work in CAREL's thermodynamic research centers.

A further evolution came in 2016, with the creation of the Knowledge Center, even if unofficially this already existed.

Indeed, it had become necessary for those who worked in the research center to provide sales and after-sales support in the company, as well as to disseminate the skills acquired at the research center not only across the company, but also externally, participating in international conventions and conferences and demonstrating CAREL's significant expertise.

In 2023, after almost 20 years, the research center at Headquarters will move to the brand-new CAREL 5 building. The new 1200 m2 area will see the construction of three very modern climate test chambers, compatible with the use of flammable refrigerants, for the purpose of working on what will be the company's most important project in coming years: heat pumps. The total investment is more than eight million euros, including the energy efficiency class A4 building - the highest class in Italy - and equipment both in the research center itself and in the building's showroom and training areas.

Have any ideas for products come out of the research center? If so, which ones?

There are two products that have marked the history and success of the thermodynamic research center. Electronic expansion valves and drivers – also called inverters – for variable-speed compressors. Each comprises a somewhat complex ecosystem of components, skills and activities, and both required several years' work and hundreds of trials before evolving into mature products. And fortunately, the efforts have paid off. Indeed, these form the heart of many of CAREL's solutions that guarantee its customers exceptional performance, above all in terms of efficiency and environmental sustainability. It is no coincidence then that in the years following 2010, the research center dedicated itself to a whole series of "high efficiency" applications, aimed at fully exploiting the potential of these two fantastic products.

There are two products that have marked the history and success of the thermodynamic research center. Electronic expansion valves and drivers – also called inverters – for variable-speed compressors. Each comprises a somewhat complex ecosystem of components, skills and activities, and both required several years' work and hundreds of trials before evolving into mature products. And fortunately, the efforts have paid off. Indeed, these form the heart of many of CAREL's solutions that guarantee its customers exceptional performance, above all in terms of efficiency and environmental sustainability. It is no coincidence then that in the years following 2010, the research center dedicated itself to a whole series of "high efficiency" applications, aimed at fully exploiting the potential of these two fantastic products.