Production of bread and rusks (crisp bread)

-

ลักษณะทั่วไป

Food industry requires an accurate control of air temperature and humidity, both in the production stages and during the subsequent storage. Therefore, it needs systems able to provide the optimal conditions required to ensure maximum efficiency and hygiene of the process and top quality of the product.

For example, inside the bread leavening cells, the relative humidity of the air must be maintained above 75%, in order to prevent the bread surface from getting dry during leavening and first baking.

If the air is too dry during bread leavening, the crust cracks, which can alter the flavour and compromise the appearance of the product. In addition, dampening the surface of the dough with a steam jet prior to putting it in the oven, gives the bread a shiny crust.

The production of rusks (crisp bread) and biscuits as well requires a relative humidity above 75% in order to allow the wafer to leaven without drying out and to ensure a fragrant and light product.

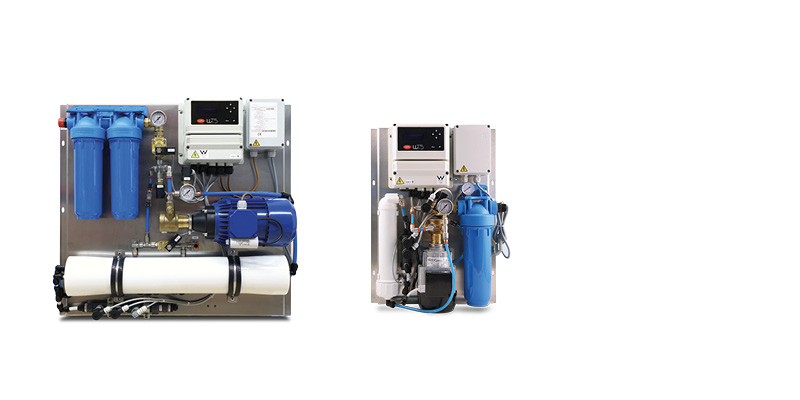

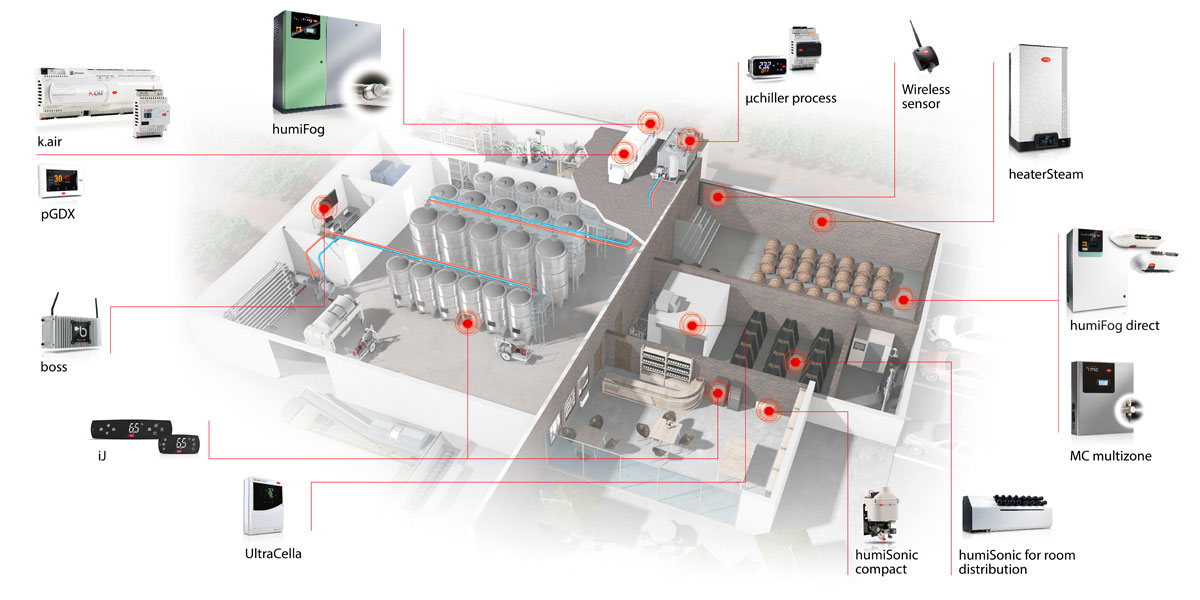

Thanks to its 40 years of experience, Carel offers a wide variety of humidifiers, both with steam and adiabatic, in a wide range of features and operation modes. The adiabatic systems have the advantage of ensuring minimum energy consumption, since they operate by spraying water (mains, softened or demineralized water) into millions of tiny droplets that evaporate spontaneously into the air, humidifying it. For the most efficient systems, the power input barely reaches 4W per litre of atomized water, less than 1% of the power input of a regular steam humidifier. The steam systems, on the other hand, are suitable for smaller humidification loads, or where steam is required to maintain proper levels of humidity in the oven, or to condition the surface of the products before entering the oven, or after they are taken out of the same. -

เพิ่ม

Preserving the air humidity in order to: - Optimize the leavening process, while limiting the formation of cracks on the product's surface and to control the thickness of the crust;

- Guarantee the right baking and achieve the desired appearance and fragrance.