Increase the efficiency of your chiller or fluid cooler with chillBooster!

Perfect for retrofits...

Everyone knows that the climate is changing: average temperatures continue to rise, year after year. Even though the priority must be to try and put a stop to this process by using green technologies to the greatest possible extent, it is likewise essential that existing systems, installed and designed a few years ago, can continue to work correctly despite the changing conditions. One important example is cooling in supermarkets. Cooling systems, which work by transferring heat from one area to another, are sized by the manufacturer based on the ambient temperature in the place where they are installed. However if this increases, a decline in performance is inevitable.

The CAREL chillBooster offers a solution to this problem. Its cabinet houses a pump that pressurises water and sprays it through the nozzles installed in the distribution system. This atomised water removes heat from the air through evaporation, thus naturally cooling the air. The result is that the air entering the fluid cooler is cooled (by up to 5°C - 10°C) below ambient temperature.

…but also for new installations!

chillBooster technology is also ideal for new installations. A fluid cooler, whether a liquid cooler, condenser or gas cooler, can have a smaller heat exchange surface if designed to work with the Carel system, when compared to an equivalent unit without chillBooster. This is because the difference in heat exchange is guaranteed by the lower air temperature. As a result, the fluid cooler can be smaller and thus more economical.

Main benefits

Hygiene

Hygiene

Automatic emptying of the distribution system and the UV lamp in the cabinet prevent stagnation of water and the spread of bacteria.

Service continuity

Service continuity

Evaporative cooling ensures service continuity by mitigating the effect of high summer temperatures.

Very low energy consumption

Very low energy consumption

Extremely low power consumption: a dry cooler system with an air flow-rate of 200,000 m3/h atomises 1000 l/h with power consumption of less than 0.7 kW.

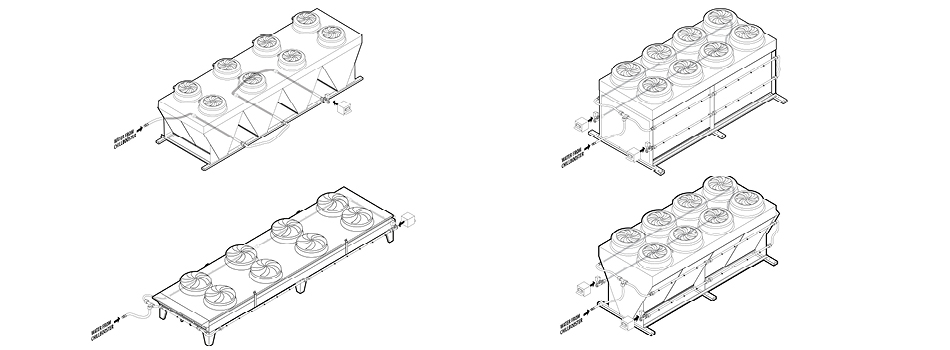

An extremely versatile product

The cabinet has been designed to also be installed outdoors near the fluid cooler, while the extreme flexibility of the distribution system makes chillBooster suitable for any shape of coil. Vertical, horizontal, “V” or “W”; all four sides or some sides only, it makes no difference: chillBooster offers a solution in every scenario to fully meet the system requirements.

A range to complete the solution

The wide range of CAREL products includes everything needed to complete an evaporative cooling solution for fluid coolers. Starting, of course, with the chillBooster itself, CAREL also offers customers a series of products ranging from temperature and pressure probes to an electrical panel for managing the chillBooster unit.

The wide range of CAREL products includes everything needed to complete an evaporative cooling solution for fluid coolers. Starting, of course, with the chillBooster itself, CAREL also offers customers a series of products ranging from temperature and pressure probes to an electrical panel for managing the chillBooster unit.

Success story

CAREL has completed a case study together with Delhaize Le Lion / De Leeuw, a large Belgian retailer. This includes all of the details of the project involving the installation of 120 chillBooster units in more than 100 supermarkets throughout Belgium over the period 2019/20.

CAREL has completed a case study together with Delhaize Le Lion / De Leeuw, a large Belgian retailer. This includes all of the details of the project involving the installation of 120 chillBooster units in more than 100 supermarkets throughout Belgium over the period 2019/20.

CPQ Selection tool

The correct sizing and selection of all of the components in a HVAC/R system are essential to be able to offer customers the best solution. This is the concept that underlies the development of CAREL CPQ: the tool created to simplify the work of our partners, a guide for sizing, selecting and even configuring CAREL products.

The correct sizing and selection of all of the components in a HVAC/R system are essential to be able to offer customers the best solution. This is the concept that underlies the development of CAREL CPQ: the tool created to simplify the work of our partners, a guide for sizing, selecting and even configuring CAREL products.

The ChillBooster has recently been expanded and updated to make selection even simpler. Below is the link to a video that, in just a few minutes, explains how simple and versatile this tool is.